Ecoprogetti, a Northern Italian company, offers high-end sun simulators, laminators, tabber and stringers, among other products, for solar module manufacturing. Since 1998, hundreds of machines have been sold worldwide. Thanks to the real-life customer experience and the in-house solar module process machines, Ecoprogetti has been able to continuously improve their products.

Core competencies have evolved with lamination and cell tabbing and stringing technology. “TECHNOLOGY AT THE SERVICE OF THE ENVIRONMENT, DEVELOPMENT COMPATIBLE WITH LIFE”. This is the philosophy which moves Ecoprogetti in the search for new technologies and applications in the field of renewable energy.

HELPFUL LINKS: Click on these links to jump to that section.

Tabber and Stringers

Solar Cell Layup-Ecolay Up 100

Cut Solar Cells

Automated Bussing

Solar Turn-key Solutions

![]()

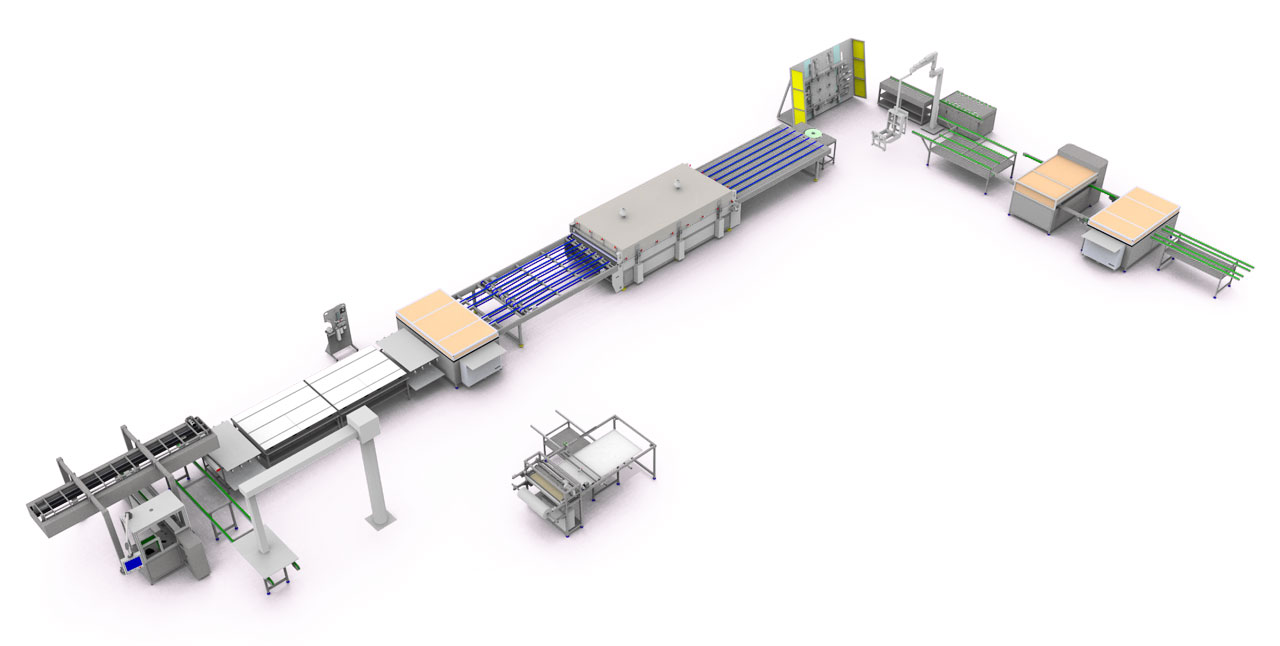

Solar Turn-key Solutions Features:

Ecoprogetti’s solar turnkey solutions which come “ready to use” are compositions of manufacturing equipments in combination with a wide range of services all put together to create a complete path for the production of high quality photovoltaic modules.

The success of the module manufacturer is strongly linked with the choice of partners. Ecoprogetti, in order to guide the customer in the right direction towards success, designs and proposes specific pv module assembly lines tailor made according to the customers’ needs.

- Projects consider balancing the number of operators to be occupied in the production line;

- Optimization of the design and structure of the turn-key plant listening to the customers’ needs and requirements;

- Modularity when designing, for a future expandability.

Tabber & Stringers • ET7003B, ETS700, ETS1800

Ecoprogetti offers a line of automatic tabbing and stringer machines:

Ecoprogetti’s Tabber & Stringer System.

Features:

- High soldering quality;

- Possibility to change cell size in less than 20 minutes; Only one worker for three machines;

- No handling contact;

- Special designed for thin solar cells, 160 micron;

- Variable space between the 2/3 ribbon;

- Adjustable tab length;

- Adjustable soldering length;

- Touch-screen control;

- Troubleshooting on line to the touchscreen;

- The number of solar cells for the strings is settable from the touchscreen;

- Adjustable distance between the cells from 2 mm to 50 mm;

- No pre-treatment of the ribbon is necessary;

- Equipment has very little need of maintenance and all maintenance work can be performed by the operator without calling Ecoprogetti’s technicians;

- Quick assistance via internet.

Features of the ET7003B:

- Innovative hybrid welder allows to solder without mechanical and thermal stress, this is indicated for very thin solar cells and for ribbon cells (EFG);

- Available also with laser soldering system that is indicated also for lead free ribbon;

- High flexibility – the machine is suitable for all types of standard photovoltaic modules but also for BIPV modules;

- High soldering quality; more than 300 N in peel test over the complete cell surface;

- Possibility to change from 2 to 3 bus bar cells in less than 1/2 hour;

- Automatic change of cell load basket;

- Pre and post heating of the cell in soldering phase in order to avoid thermal stress;

- Heating and stretching of the ribbon before soldering;

- Fluxing and drying of the ribbon before soldering;

- Variable space between the 2/3 ribbon;

Optional:

- Laser soldering;

- Automatic unloading of the strings and positioning on the glass with EVA;

- Cell alignment by camera control;

- String flipper on unload belt;

Solar Cell Layup-Ecolay Up 100

Solar Cell Layup-Ecolay Up 100 Features:

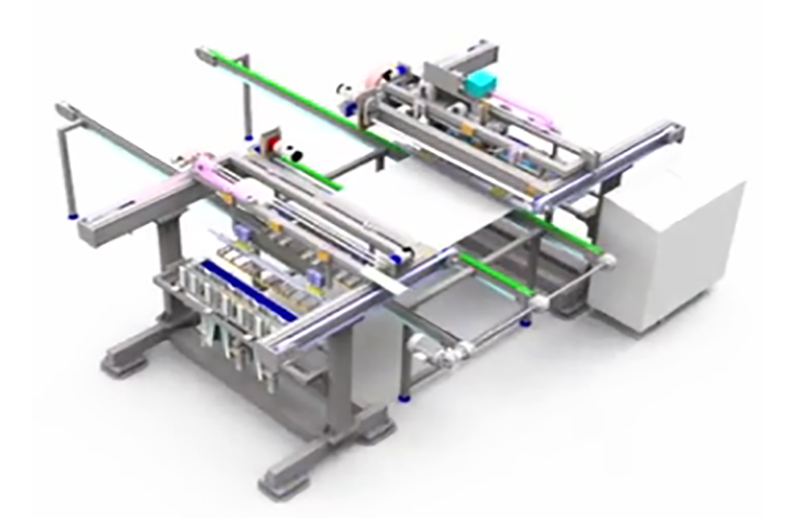

Automatic equipment for compose PV module over the glass

ECOLAY UP 100 picks up and positions the strings coming out of the solar stringers on the glass with EVA.

A load arm, with the help of vacuum, picks up the strings and turns them clockwise or anti clockwise before positioning them on the glass already prepared with the first layer of EVA.

The glass enters in the machine on a motorized conveyor belt.

The number of strings per glass is settable from the touch screen and when the module is ready it’s automatically unloaded.

Features:

- 1400 cells / hour (2 stringer machines ET700-3B). Possibility to handle 2100 cells / hour (3 stringer machines ET700-3B can be offered as optional)

- User friendly and simple to integrate in existing manual production lines

- Maximum module size 2000 x 1200 mm. Possibility to handle bigger modules can be offered as optional

- Parameters settable from touch-screen

- Analysis of failures from touch-screen

- Quick and easy change of cell and module type

- This machine has very little need of maintenance and all maintenance work can be performed by the operator without calling Ecoprogetti’s service lines

- Quick remote assistance via internet

- Dimensions: Height 2000mm, Width 4600mm, Length 6200mm, Weight 980kg

Cut Solar Cells

Cut Solar Cells Features:

Features:

- The special kit for Ecoprogetti tabber stringer machine is designed for manage and sold cut solar cells from 52x156mm to full cells 156x156mm

- Thanks to this kit is possible to make automatic and reliable the process for manufacturing the solar panels with small solar cells

- The cut solar cells, are used to produce photovoltaic modules of small size but with a working voltage not too low. Indeed the cut cells permit to have a greater number of cells in the circuit of the panel, to obtain a higher output voltage

- The kit for cut solar cells permits to extend the capability of the CTS (Combined tabber and stringer) ET700

- The tabber stringer machine maintain the ability to manage the standard cells and also have the possibility to manage smaller solar cells

- This garantee a high flexibility of the entire PV module production line

Flexibility of the production:

The kit for cut solar cells permits to extend the capability of the CTS (Combined tabber and stringer) ET700.

The tabber stringer machine maintain the ability to manage the standard cells and also have the possibility to manage smaller solar cells.

This guarantee an high flexibility of the entire pv module production line. Infact it’s possible to produce both standard solar module (eg: 60cells 250W) and also smaller module with cut solar cells.

So it’s possible to change from one configuration to the other in one hour.

Automated Bussing

Automated Bussing Features:

Automated bussing by eccoprogetti. Ecoprogetti’s bussbar soldering solution!

- Interconnection with PCB

- Stable and reliable soldering

- Reduced labor

- High throughput

Laminator • Ecolam 6040

Ecolam 6040 Laminator Features:

Features:

- Developed for R&D purposes in order to perform the lamination process with the same exact precision as the bigger laminators of the same series

- This unit has become very popular among raw material manufacturers that use it to develop and improve materials for the photovoltaic industry

Characteristics:

- Temperature range: From room temperature to 180 C°

- Temperature uniformity: 2 C°

- Max. thickness of laminate: 20 mm

- Operator control: Easy programmable software

- Touch-screen panel

Dimensions:

- Laminator size 900x600mm

- Useable area 600x400mm

- Weight 400kg

Laminator • Ecolam 08

Ecolam 08 Laminator Features:

Common Features::

- Capable to laminate standard photovoltaic modules, as well as prismatic glass, double glass, transparent tedlar and flexible modules; also laminates colored plasma screens;

- The lamination cycle is automatic and controlled by a PLC;

- Touch screen operation to control the cycle, the temperature and the vacuum values. Troubleshooting directly on the touch screen with alarm message

- Low energy cost. Alarm message when maintenance is needed; quick assistance via internet.

Features of ECOLAN 08:

- Allows lamination in series of the photovoltaic modules using an automatic conveyor belt for the centring, loading and unloading

- Lamination cycle with a continuous temperature of 180 °C for an ultra fast cure EVA

- Possibility to set different temperatures in 12 different zones

- Long lifetime of the silicone membrane; easy and fast membrane change in only 20 minutes Automatic release sheet in Teflon on both sides of the modules

- Vacuum dry pump + booster pump as standard

- Cooling system at close circuit for vacuum pump as standard

- Cooling of the modules on the unload belt as optional

Laminator • Ecolam 08 Maxi S

Ecolam 08 Maxi S Laminator Features:

Features:

- Load belt with module centring – Laminator – Unload buffer with capacity to store 31 modules;

- Load buffer with module centring and capacity to store 31 modules – Laminator – Unload belt;

- Load buffer with module centring and capacity to store 31 modules – Laminator – Unload buffer with capacity to store 31 modules;

- Double step lamination that doubles the lamination capacity:

- Load buffer with module centring and capacity to store 31 modules;

- Laminator for pumping time;

- Laminator for curing time;

- Unload buffer with capacity to store 31 modules

- The lamination cycle permits to laminate with a continuous temperature of 180 °C which permits an use of ultra fast cure EVA

- Possibility to work with a continuous work temperature of 180 °C;

- Possibility to set different temperatures in 12 different zones;

- Membrane change in less than 20 minutes with quick clamp system with plates in working temperature;

- External pump housing composed one principal vacuum pump, one back up vacuum pump and a special filter to absorb the EVA gasses for a full ambient respect;

- Internal booster pump to improve and reduce the pumping time;

- Automatic release sheet in Teflon on both sides of the modules;

- Cooling of the modules on the unload belt as optional;

Dimensions:

- Laminator size 5570 x 2820 mm

- Usable area (width x length) 4400 x 2000 mm

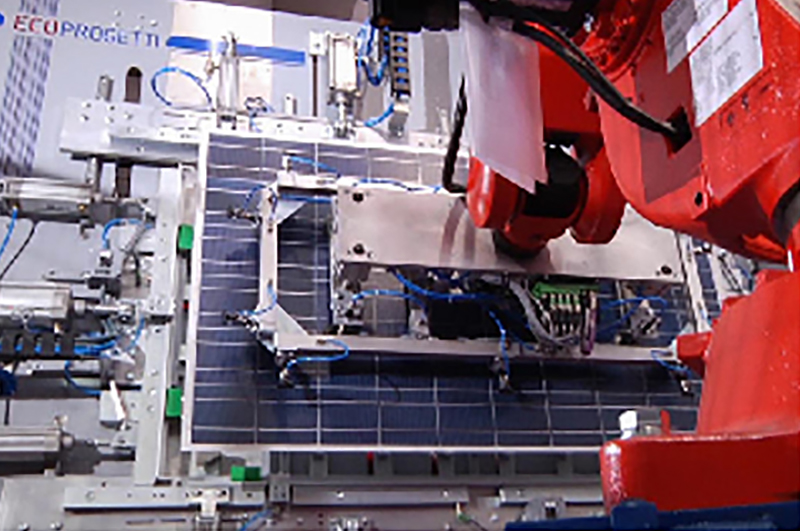

Framing System • Automated

Automated Framing System Features:

- Fully automatic framing island mainly composed by a 6 axis robot,

ECOFRAME VERTICALE and ECOSIL 08,

all controllable by touch-screen - The modules enter in the framing station with the backsheet up

to avoid turning them after lamination - Modules exit from the framing station with the backsheet up

ready in position for the installation of the junction box - Motorized belts for the loading and unloading of the framing island

- No silicone cleaning after framing necessary

- One module every 90 seconds

- Reduced labour

- Quick remote assistance and supervision via internet

Optional

- Automatic trimming of the modules

- Additional module sizes

Manual (Horizontal & Vertical) Framing Equipment also available.

J-Box Dispensing

J-Box Dispensing Features:

Features:

- Easy programmable silicone dispenser with X-Y movement working around the perimeter of the junction box

- Junction box is attached manually on the module and the operator makes the connection between the ribbon and the diodes

Function Requirements and Others:

- Electrical 220 V

- Peak power 0,5 kW

- Frequency 50-60 Hz

- Compressed air 6 BAR

- Dimensions: 800 x 800 x 800 mm

- Weight: 40 Kg

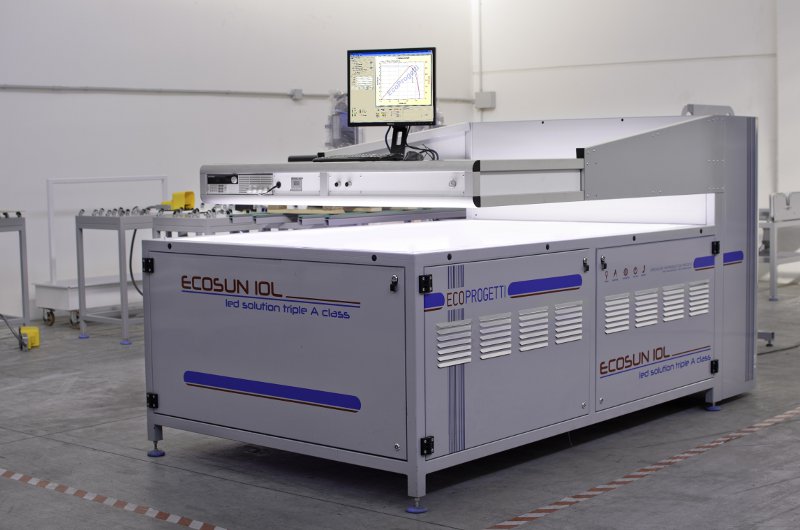

Sun Simulator • Ecosun 10l

Sun Simulators for Thin film and Wafer Technologies:

Ecoprogetti is proud to introduce their new sun simulator ECOSUN 10L, based on LED technology. The ECOSUN 10L is in full accordance with the AAA class standards. This new product will improve the work flow of the production line thanks to Ecoprogetti’s LED technology, with which it’s possible to obtain extremely high performance with minimum required production space. Also, the compact and new ECOTESTSUN gives the clientele the opportunity to test their individual cells at either their own pace or at high speed. Also, New ECOSUNPLUS !!!

Features:

- Long-lifetime, LED technology; reliable and low maintenance costs

- Compact design

- No recharging time is needed between tests

- Possibility to personalize the test impulse duration

- For crystalline and thin film products, in compliance with triple A class and norm EN 60904-9

Dimensions:

- Height 1550mm

- Width 1600mm

- Length 2900mm

- Weight 800kg

Pick & Place Sorting

Pick & Place Sorter Details:

Ecoprogetti’s sun simulator ECOSUN 10L can be interfaced with an automatic classification system which divides the modules in various categories according to the electrical characteristics of the tested module, programed easily by an operator.After the test performed by ECOSUN 10L the module is picked up by an horizontal axis and delivered to its corresponding pallet.The number of categories/pallets that the system manage to control is personalized according to the customer’s requirements.

Dimensions:

Height: 2550 mm

Width: 2250 mm

Length: 6000 mm

Weight: 2000 kg

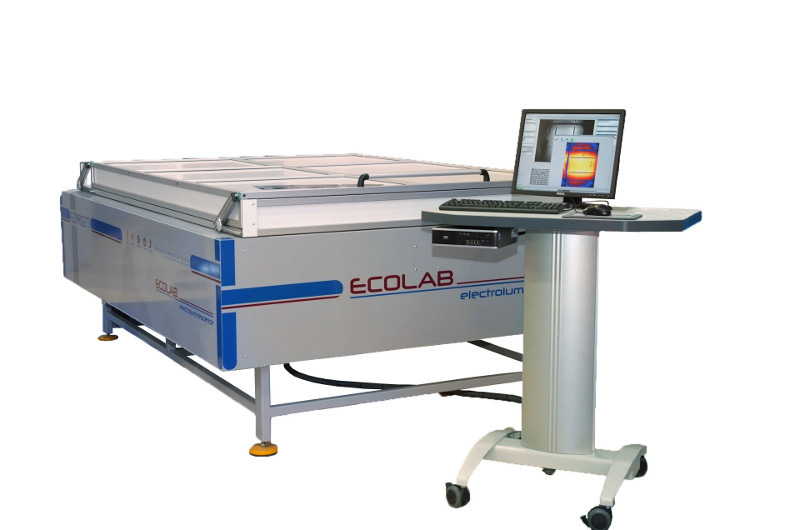

Electroluminescence Tester • ECOLAB 10-EL

Ecolab 10-EL Features:

Ecoprogetti’s new work station that performs an electroluminescence test of the module expresses Ecoprogetti’s philosophy in promoting the research of new solutions and technologies to improve the quality of the product. This machine permits the user to perform a deep extensive control of the production, permitting continuously to improve the process based on the raw material in use. Also, New models 2017 !! Ecolab 102-102 A and 103-103A

Features:

- offers to the user the maximum possible resolution;

- it’s possible to test single cells or strings not yet laminated.

Dimensions:

- Height 930mm

- Width 1950mm

- Length 2800

- Weight 300kg

Buffers

Buffer Features:

ecoprogetti’s temporary module storage in the production line ! it works autonomously and it is provided with plc and electrical control panel. it can be installed wherever needed in the production line where bottlenecks can be created, such as during the change of material spools in the inline cutters and when changing the silicone membrane in the laminator.

- Possibility to store up to 31 modules

- Ethernet communication for an easy interface with other equipment

- Can be delivered complete with module alignment to simplify loading of ECOLAM S and Speedy framing group

- Alarm message when maintenance is needed

- Little need of maintenance; work can be done by phone call

- Quick remote assistance and supervision via internet

- Lifo System

Traceability System

Traceability System:

Ecoprogetti offers an innovative solution for the traceability, management and supervision of the production process for the photovoltaic module industry.This software solution permits to gain information from the various process phases which improves both the management and the traceability of the product and optimizes the work-flow in each single phase.

With the software it’s possible to consult and control the production trend, supervise the quality of the finished product, control the production and shipments.